How to Wire a Trailer That Actually Passes Safety Inspections

Trailer electrical systems seem relatively simple but there are certain considerations required for successful safety inspection that most builders don’t realize. Many DIY trailers fail safety inspection through minor oversight with the electrical wiring rather than chassis integrity. This could have been avoided with proper planning and construction.

When the difference between a safety inspection approval and denial is an easy fix, it’s often something small that someone new to installing wires wouldn’t know how to approach. For example, safety inspectors are actually looking for specific things which, if known ahead of time, could save the builder time, money, and frustration.

Recognizing Required Functions

Certain functions are required for all trailers to be road worthy. Each function has requirements for visibility, placement and distance in order for a trailer to be road worthy. The basic requirement includes tail lights, brake lights, and turn signals. Standard trailer widths (anything over 80 inches wide) also requires side marker lights. Anything over 14 feet in length additionally needs clearance lights and reflectors.

Where builders go wrong is believing that as long as the lights work, they’re in compliance. Lights have distances in which they must be visible through DOT regulation. Tail lights must be visible from 500 feet away, brake lights from 300 feet away. The lights must also be visible from the side as well as from behind the trailer.

One of the best resources a builder can access is a trailer wiring guide in order to ensure proper function and placement throughout construction. Placement is not arbitrary; placement is designed for other drivers to receive maximum warning to stop or avoid the trailer moving or parking.

For instance, when builder overlook the need for side marker lights on wider trailers, these are only required for trailers wider than 80 inches. These markers must be placed toward the middle of the trailer and be visible from the side. The front markers must be amber; the rear, red.

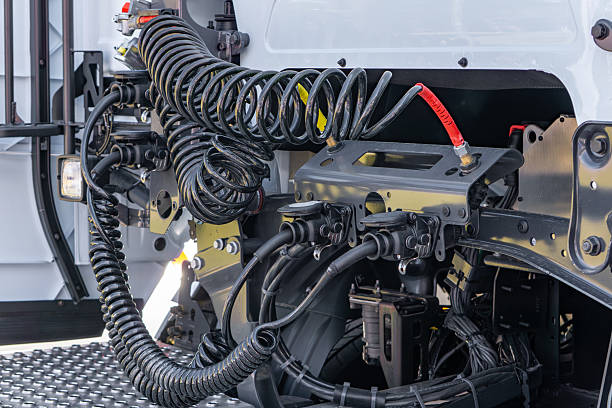

Recognizing Required Connectors

The connection between the trailer and vehicle must be compliant with those standards. The most common connections are 4-way, 6-way and 7-way connections. Generally speaking, a 4-way is used for a basic lighting system, a 6-way is used for added trailer features and a 7-way is used for brake, auxiliary, and backup functions.

But not every configuration works for every wiring setup. For example, without a 7-way connector for a trailer with brakes, it’s likely these trailers won’t pass inspection because an improperly wired connector does not create compliant operation.

Gauge size also matters more than people realize during the construction phase. If the wires are too thin, they will cause voltage drops which cause lights not to function effectively—if at all—and could cause overheating of physical wires. Most wiring needing 14 gauge minimum; most lighting functions need 12 gauge wire minimum if length of wire run is extensive.

Wire placement also protects against damage from debris, moisture and vibration. Automotive-grade wire ensures proper insulation; placement protects from sharp edges and vehicles it too close.

Recognizing Grounding Systems

Grounding systems are often overlooked and incomplete—leading to shorts and poor function. Grounding wires connected to any part of the metal are not sufficient enough for proper grounding systems.

The most extensive grounds should come from the connector ground wire to ensure there’s an electrical connection between the vehicle and trailer framing. This helps establish connection through the trailer frame itself which needs good interior grounding systems.

However paint chips, rust and poor connection cause high resistance which translates to dim lights or shorts. Additionally each individual light fixture needs reliable connection back to the frame or a ground wire back to the main grounding system.

Using star washers or appropriately grinding paint away at grounding connections ensures reliable systems.

Recognizing Routing Requirements

How wires are routed makes a difference not only for reliability but visibility during inspection. Wires hanging down too low or getting cut on sharp edges will fail inspection.

Typically—assuming there’s enough clearance—wires must be run along the inside of a trailer frame if applicable so there can be no interference with loading/unloading processes.

Where this isn’t possible, other tubing options must protect wires from damage through splitting or wear and tear from moisture exposure. Strain relief at connections help avoid breaking wires thanks to inherent vibration and a lack of allotted slack.

Recognizing Testing Prior to Inspection

Every function must work before an inspection through direct load testing before submitting it for approval—and ideally multiple times before showing the inspector.

If turn signals don’t flash it’s because the load resistors are wrong. If brake lights don’t function independently from tail lights, either voltage is too high or improper connection exists.

Many inspections fail by failing to complete flash-rate testing on working connections to ensure brightness is sufficient for required distance markers for all lights.

Where good wiring systems can fail for pre-existing trailers is LED lights installed on older tow vehicles that don’t necessarily recognize this different bulb draw unless load resistors/flasher adjustments are made.

Recognizing Common Failure Points

Specific systems fail consistently at inspection: lights that are not bright enough—wired by those who forgot to gauge sizes and secured unfortunate voltage drops; turning signals that can’t flash because they’re wired from one signal instead of grounded appropriately; improper ground crossings that fail inspections; invisible markers that can make them noncompliant; electrical connections made with four different colors when black/red/yellow/green use should have been followed.

Avoiding shorts due to exposed connections should help prevent all systems from failing safety inspection.

Recognizing Reliability Measures

Building a functional system that passes initial inspection is only half the battle—it must continue to function safely for up to fifteen years post-construction unless there is maintenance access along the way.

From component quality to heat/construction considerations, ensuring systems are wired properly before construction solidifies reliability over time.

Marine-grade components are best vs automotive-grade systems which will get corroded over time while sealed connectors must drain properly with no opportunity for water ingress which leads to corrosion then shorts.

Consistent testing of all wiring systems before and after loads prevent minor issues from becoming big problems. A successful trailer light system is as functional as it is easy for inspection approval if done per specification then while wired up properly.